What are Foot Valves More?

Foot Valves More refers to specialized valves in our product line that utilize a foot-operated design to achieve higher flow rates, lower pressure drop, and reliable sealing. They are typically manufactured using all-metal or polymer materials and can operate continuously under harsh conditions such as high temperature, high pressure, and strong corrosion.

1. Structural Features: A foot-operated drive is located at the bottom of the valve body, facilitating manual or electric adjustment on-site, suitable for applications with limited piping space.

2. Technological Advantages: Precision machining and multi-layer sealing design ensure leak-free fluid flow; optimized internal flow channels significantly reduce energy consumption.

3. Applications: Widely used in piping systems in industries such as solar photovoltaic, semiconductors, chemicals, iron smelting, environmental protection, biochemistry, aquaculture, and pharmaceuticals.

4. Market Positioning: As a high-end customized product, Foot Valves More has earned customer trust in domestic and international markets for its high reliability and long service life.

How to select a Foot Valves in actual engineering projects?

1. Media Properties

Temperature and Pressure: For high-temperature and high-pressure environments, high-temperature resistant alloys or stainless steel should be selected; for low-temperature or corrosive media, corrosion-resistant alloys or fluoroplastic liners are preferred.

Viscosity and Particle Content: For viscous fluids or fluids containing solid particles, self-cleaning structures or filter-type foot valves are recommended to prevent clogging.

2. Flow Rate and Pressure Drop Requirements

Determine the valve orifice area through fluid dynamics calculations; if the system is extremely sensitive to pressure drop, select a large-diameter, low-resistance foot valve.

For processes requiring precise adjustment, electric or pneumatic actuators can be selected for automatic control.

3. Installation Space and Maintenance Convenience

Foot-operated structures are suitable for sites with limited pipeline space; for frequent maintenance, quick-release valve bodies can be selected to reduce downtime.

Consider the valve's flange size and connection method to match existing pipelines to avoid secondary modifications.

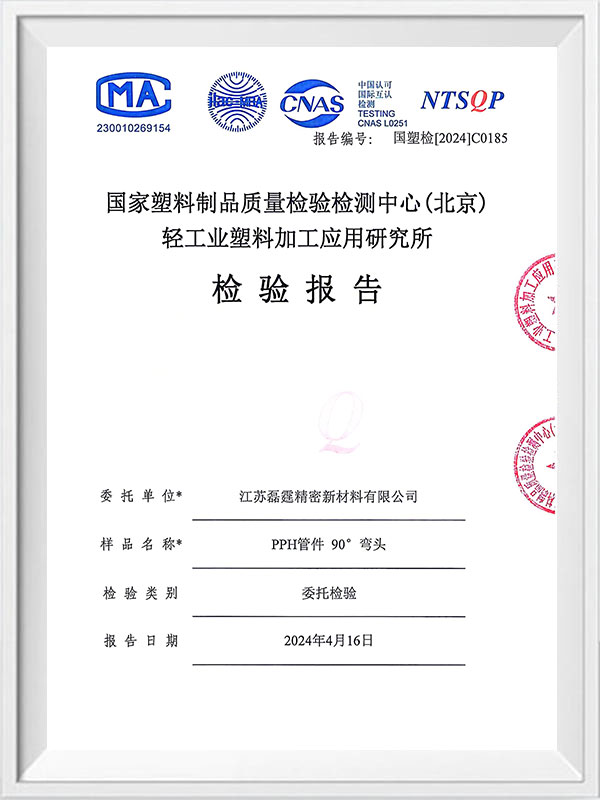

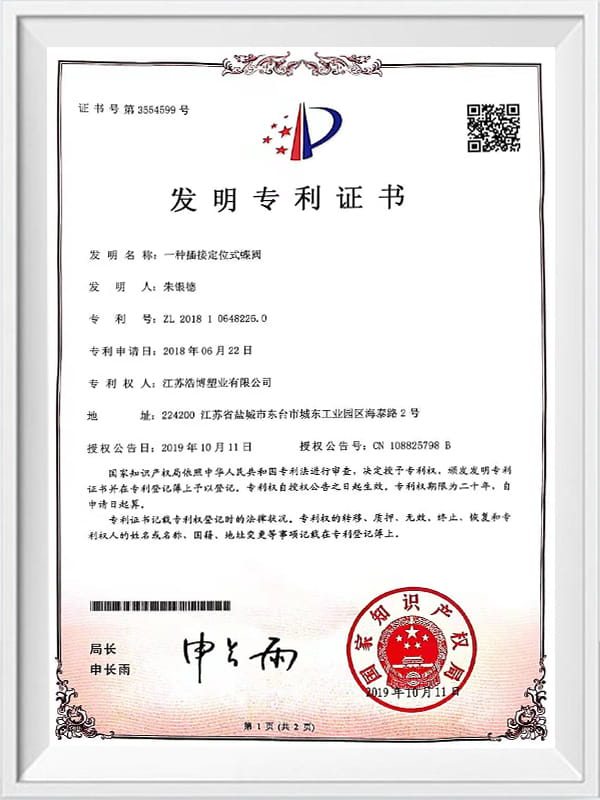

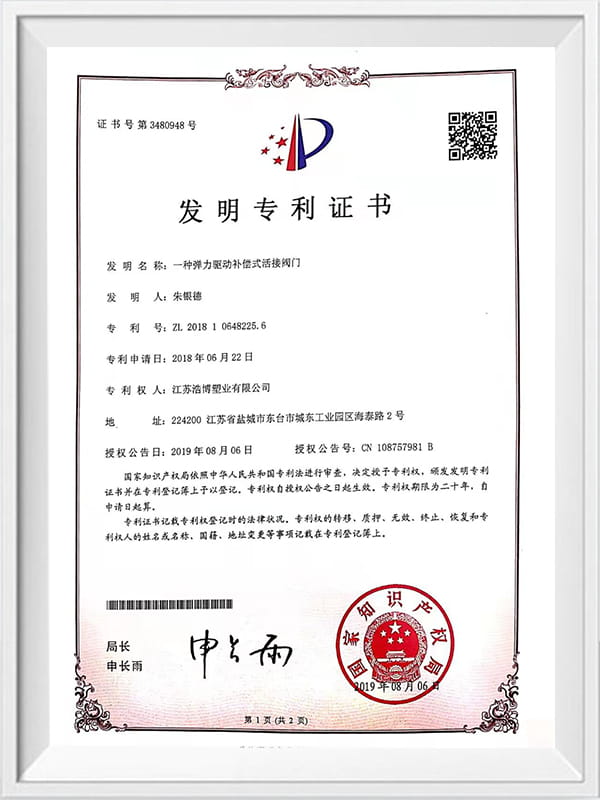

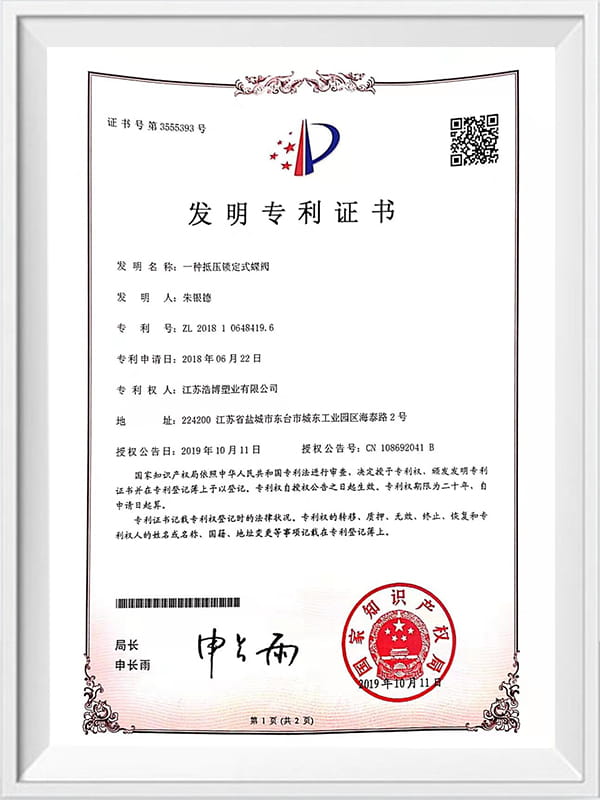

4. Standards and Certifications

Confirm that the valves comply with quality systems such as ISO9001, CE, and API; for specific industries, they must meet regulatory requirements such as GMP and USP.