What are the installation methods for Plastic Pipe Fitting Other Accessories?

1. Heat Fusion (Heat Melting): Using an electric heating device, the pipe ends are heated to their melting point, allowing the two pipe sections to quickly butt together at high temperature and then naturally cool to form a strong joint. Suitable for materials such as PVC and PE.

2. Electrofusion (Electrofusion Welding): The interior of the polyethylene pipe is heated by electric current, causing localized melting. Electrofusion fittings are then inserted, achieving a high-strength, leak-free connection. Commonly used for large-diameter pipelines.

3. Solvent Bonding (Adhesive Bonding): Special solvent adhesives are used to form chemical bonds on the pipe ends and fitting surfaces. Simple to operate, suitable for PVC pipe fittings in water supply systems.

4. Mechanical Thread/Nut Sealing Ring: Fittings are quickly assembled using threads or nuts with sealing rings, facilitating disassembly and maintenance. Commonly used for PP pipe fittings and in applications requiring frequent replacement.

How to determine if Plastic Pipe Fitting Other Accessories are of acceptable quality?

1. Appearance and Surface Integrity: Inspect fittings for cracks, scratches, or deformation. The surface should be smooth, free of oil stains, and free of residual adhesive; substandard appearance can lead to seal failure.

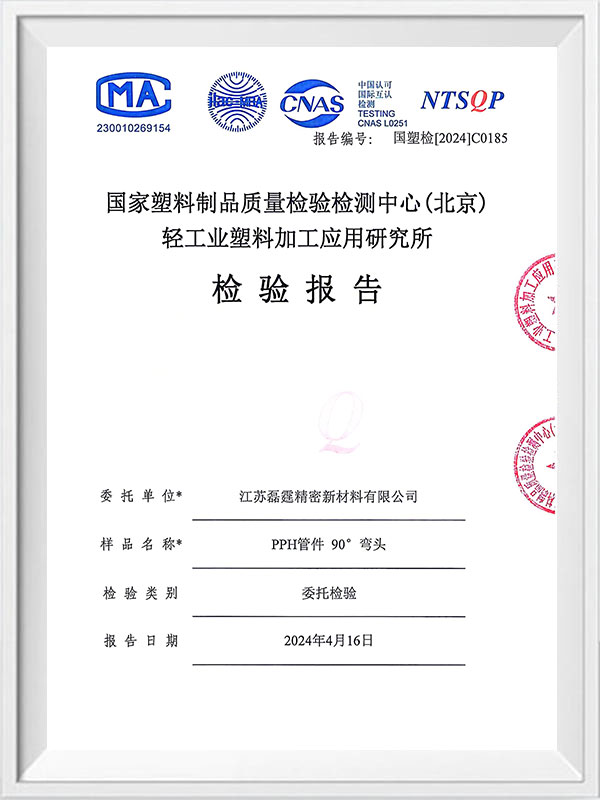

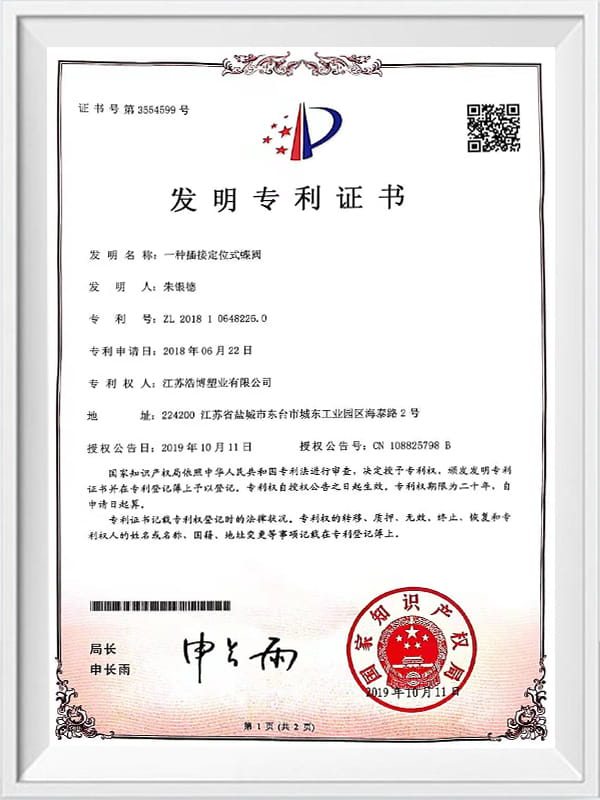

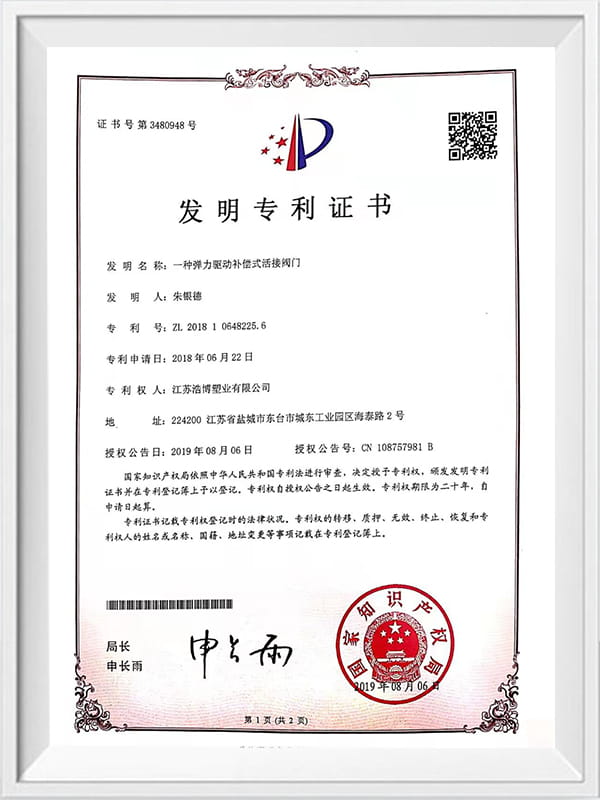

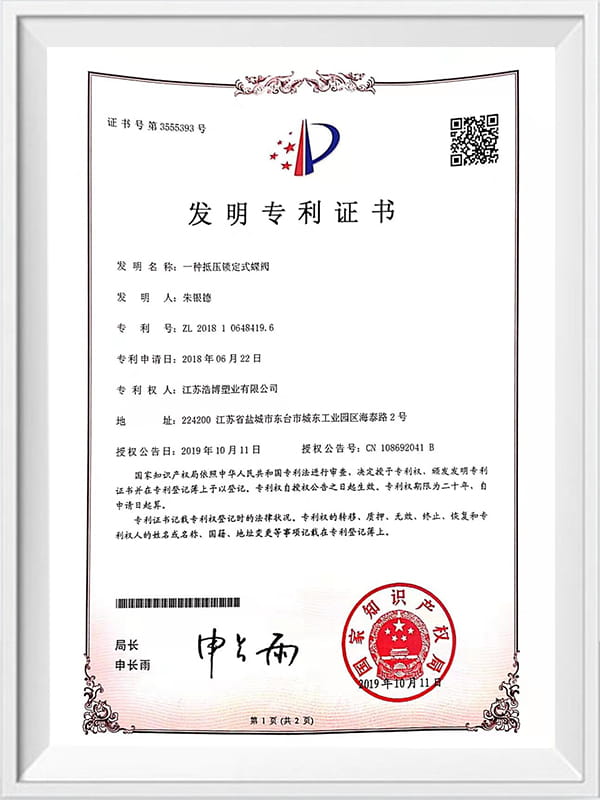

2. Material Certificates and Test Reports: Require product certificates, material inspection reports, and adhesive certificates to ensure raw materials meet national or industry standards.

3. Sealing and Leakage Testing: After bonding or welding, conduct pressure or water pressure tests to observe for leaks. Leaks are often caused by uneven bonding, uncleaned surfaces, or ineffective adhesive.

4. Installation Process Records: Maintain on-site records of key processes such as cutting, scraping, cleaning, heating, and bonding to facilitate quality problem tracing and process control.