β--PPH Handle-type Operated Butterfly Valve

Easy to open and close, low fluid resistance, and simple structure. When fully ...

View MoreFirst of all, flow rate = flow rate ×inside diameter of the pipe× inside diameter of the pipe ×π÷ 4; so flow rate and flow rate can basically figure out another parameter by knowing one.

But if the pipe diameter D and the pressure inside the pipe P are known, can the flow rate be calculated?

The answer is: you can’t find the flow rate and flow rate of the fluid in the pipe yet. You imagine that there is a valve at the end of the pipe, and when it is closed, there is pressure P in the pipe, and the flow rate in the pipe is zero.

So, the flow rate in the tube is not determined by the pressure in the tube, but by the downward slope of the pressure in the tube along the way. So be sure to state the length of the pipe and what is the pressure difference at both ends of the pipe to find the flow rate and flow rate of the pipe.

If the relationship between pressure and flow in a pipe is directly proportional from a qualitative analysis point of view, that is, the greater the pressure, the greater the flow. The flow rate is equal to the flow rate times the section. For any section of the pipe, the pressure comes from only one end, that is to say, the direction of the pressure is one-way, and when it is closed at the outlet in the direction of the pressure (the valve is closed), the fluid in the pipe is in a prohibited state. Once the outlet is open, its flow rate is determined by the pressure in the pipe.

For quantitative analysis, it is possible to install a manometer, flow meter or measure the flow-through capacity by means of hydraulic model experiments. For pressure pipe flow, it can also be obtained by calculation, and the calculation steps are as follows:

1. Calculate the specific resistance S of the pipeline. If it is an old cast iron pipe or an old steel pipe, you can use Shevelev's formula to calculate the specific resistance of the pipeline s=0.001736/d^5.3 or use s=10.3n2/d^5.33 to calculate, or check the relevant table;

2. Determine the head difference H=P/(ρg) between the two ends of the pipeline. If there is a horizontal drop h (meaning that the starting end of the pipeline is h higher than the end), then H=P/(ρg) h

In the formula: H: in m; P: is the pressure difference at both ends of the pipe (not the pressure at a certain section), P is in Pa;

3. Calculate the flow rate Q: Q = (H/sL)^(1/2)

4, flow rate V=4Q/(3.1416 * d^2)

Where: Q —— flow rate, in m^3/s;

H —— The difference between the water head at the beginning and end of the pipe, in m;

L —— length from beginning to end of pipe, in m.

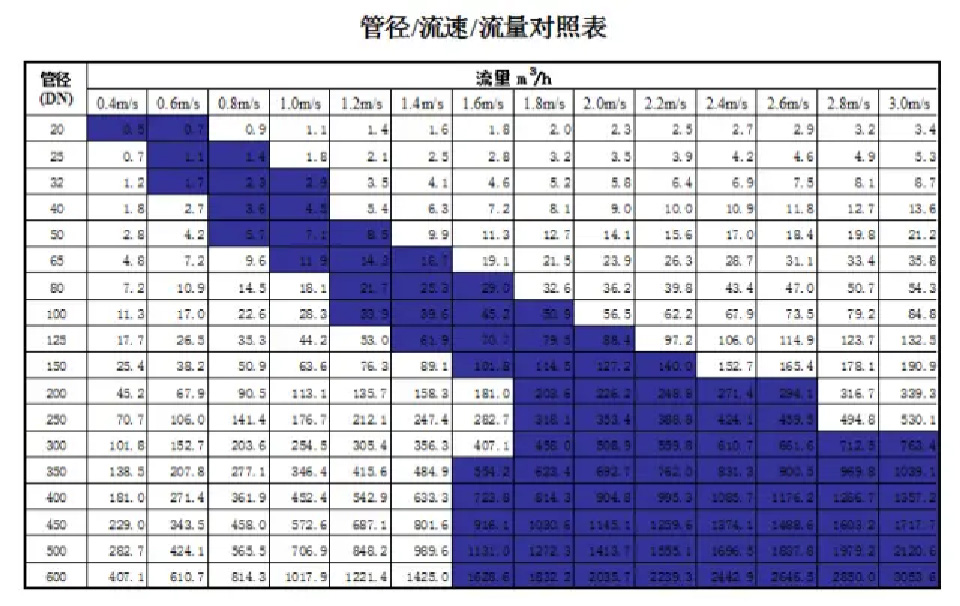

Note: The top row is flow velocity

The large piece of data in the middle of the above table is the traffic

The leftmost row is the nominal diameter of the water pipe

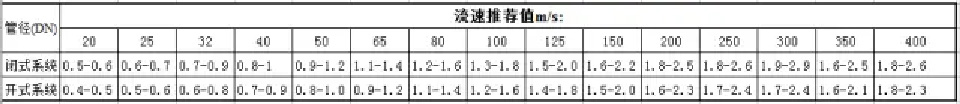

Question: "Which one should I choose with so many flow rates?"

Don't hurry... Look at the table below (there is a difference between open system and closed system)